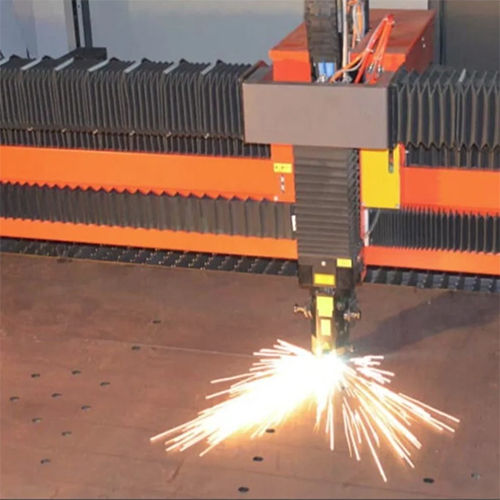

CNC Plasma Cutting Services

Product Details:

X

Product Description

Experience precision, with our CNC Plasma Cutting Services at Perfect Precision Product LLP. Our cutting edge technology guarantees flawless cuts for designs or robust industrial projects. Pay us a visit for solutions that redefine accuracy and efficiency. We offer a range of materials providing customized answers to match your requirements. Count on our experts to deliver top notch outcomes ensuring your projects are executed with finesse. Enhance your fabrication journey, with Perfect Precisions CNC Plasma Cutting Services where innovation meets excellence setting the benchmark for precision in each cut.

Precision & Efficiency with CNC Plasma Cutting

Our advanced CNC plasma cutting services offer excellent precision, with an accuracy tolerance of 0.2 mm and fast processing speeds of up to 8000 mm/min. This ensures timely project completion without sacrificing quality, making it ideal for both large-scale manufacturing and custom requirements. Each cut is optimized for smoothness and minimal finishing, resulting in consistently high-quality components.

Versatile Material and Design Capabilities

We cater to a wide range of materials including mild steel, stainless steel, aluminum, and copper. Thanks to the flexibility of CNC control, we can accommodate unique patterns and designs as per customer drawings, providing solutions for diverse industry applications.

Reliable Partner for Industrial Needs in India and Beyond

As an established exporter, manufacturer, and supplier, we pride ourselves on delivering tailored plasma cutting services from our India-based facility. Our adaptive production capabilities enable us to fulfill varying job requirements and timelines-whether for large production runs or specialized custom orders.

FAQ's of CNC Plasma Cutting Services:

Q: How does the CNC plasma cutting process ensure accuracy and quality?

A: The CNC plasma cutting process uses computer numeric control (CNC) technology to guide a high-frequency plasma torch along precise paths, achieving an accuracy of 0.2 mm. This technology, coupled with burr-free and smooth edge finishing, ensures each component meets strict quality standards.Q: What materials are suitable for your CNC plasma cutting services?

A: Our services are ideal for cutting mild steel, stainless steel, aluminum, and copper. Each material is processed to deliver smooth, burr-free edges, making the cut parts suitable for various industrial applications.Q: When should I opt for CNC plasma cutting for my project?

A: CNC plasma cutting is recommended when you require precise, smooth cuts on metal sheets with a maximum size of 3000 mm x 1500 mm. It is highly suitable for intricate patterns or jobs needing fast turnaround and accurate results.Q: Where are your CNC plasma cutting services available?

A: We operate from India as an exporter, manufacturer, service provider, and supplier, offering our CNC plasma cutting services both domestically and to international clients.Q: What is the typical process from order to delivery for customized cutting jobs?

A: Simply share your technical drawing or design with us. We will review your requirements, confirm material compatibility, provide a quotation, and upon approval, initiate the cutting process. Production capacity and delivery timelines are tailored to match your specific order size and urgency.Q: How can using CNC plasma cut parts benefit my business?

A: Opting for CNC plasma cutting ensures high accuracy and consistent quality, reduces manual finishing due to smooth, burr-free edges, and accelerates production speed-leading to cost and time savings for your business.Q: Is customization possible, and do you handle unique designs?

A: Yes, we offer complete customization based on customer-supplied drawings or designs, including unique patterns or dimensions within our maximum cutting size, to fully meet your project needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free